It’s been a decade in the making, especially since it took years for Vizibl (founded in 2013) to find it’s focus, but what was once yet another SRM (Supplier Relationship Management) platform is now a truly leading Supplier Collaboration, Innovation, and Transformation platform.

Starting out with the vision of a better SRM, it took a while for Vizibl to find its niche and double down on it. In fact, it took years of working with clients with highly specific (customization/process) needs for them to realize that they were good at developing for and supporting specific, sometimes, complex processes and years more for them to sit back and identify the commonality, design standard project and service layers, and bring them to market. But they did, and they have, and we will discuss the first major project/service layer they are bringing to market later in this article.

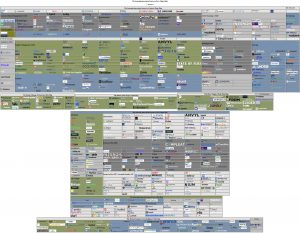

The Vizibl platform has seven main components:

- Supplier Information Management Foundation

- Supplier Collaboration Workspace

- Supplier Innovation Hub

- Supplier Relationship Management Module

- Dashboards, Analytics, and Reporting

- Program Layer: (Foundation for) Specific Development/Improvement Programs that Cross-Cut the Entire Platform

(built on a virtual platform integration layer)

- Supplier Sustainability Management

1. The Supplier Information Management Foundation is what you would expect from a leading SRM platform — it can track all of the core data and meta data you would expect on a supplier and can be extended as needed to track all of the data you require across all areas of supplier information, products, risks, compliance requirements, performance requirements, contracts, projects, initiatives, and activities you wish to manage.

Supplier Onboarding is straight forward as it’s quick and simple to create a new company record to begin the process, with only minimal data needed. New suppliers can be onboarded as standalone, children of an existing company, or related entities. The platform can maintain complex supplier tree relationships and the tree can be visualized along with a roll up of relevant metrics, project counts, and appropriate relationship data.

2. The Supplier Collaboration workspace is where the buyer can communicate with the supplier, spin off action plans and initiatives, store ideas and plans, pull in and push out data as needed, and put thought into action.

3. The Supplier Innovation Hub is where the core of the magic happens. This is where challenges can be issued, goals set, and projects planned. It’s where projects are defined to increase supplier performance, improve product designs or manufacturing, increase sustainability, or decrease CO2/GHG emissions.

Projects have activities (or tasks), roadmaps that link them together, objectives (outcomes), value tracking metrics, integrated communications, and teams.

4. The Supplier Relationship Management Module is the glue that holds it all together. In addition to integrating all of the pieces, it also supports the creation of basic supplier action/account plans, the definition of strategic objectives, and integrated overview dashboards. It also allows for the definition of supplier teams (that it calls circles) that represent the different teams the organization will be working with, the management teams, and boards of relevance.

5. The Dashboards, Analytics, and Reporting capability is used to summarize and display the various types of data, metrics, and indicators tracked by the platform. These dashboards cannot only roll up metrics across the platform, but can also roll up metrics in, and across, projects by stages, as well as break them down by regions or supplier trees.

6. The Supplier Sustainability Management module is one of their latest modules focussed on tracking and managing an organization’s sustainability initiatives. It can track all of the emissions for each supplier, those that are reporting, the associated spend, and any other GHG data of relevance to the organization. It can also track all of the data associated with ESG surveys requested by the organization, which can be custom created and as broad or deep as required.

7A. The Program Layer is the toolkit that they use to build custom cross-platform program management capability that allows an organization to tackle new, and possibly exciting, initiatives that can transform their operations, product, and / or supply chains. Programs consist of suppliers, goals and targets, indicator metrics, associated data and reporting, summary dashboards, and scores.

7B: Decarbonization as a service is the first offering from Vizibl built on the program layer that integrates all of the platform capabilities to track scope 3 carbon across the supply chain by extending the sustainability management module to focus on the import and calculation of carbon emissions by supplier over time as well as best practices and learnings that can be shared with a supplier to help them reduce their emissions through leaner production, cleaner energy sources, new production processes, etc.

When it comes to the administration of the Vizibl platform, an administrator can configure, more-or-less, everything. First of all, they can configure the organizational tree as needed to match their organizational structure and include subsidiaries and use a variable number of levels for each organizational branch. So, the organization can have the global holding company; American, European and Asian holding company subsidiaries; individual (holding) companies for each country it operates in; and, if necessary, breakdown into individual locations or divisions if needed for management purposes. You can have five levels in Asia, four levels in Europe, and three levels in the Americas if that’s what’s necessary to exactly match the organizational structure. And of course, each company node in the organizational tree can have its unique settings, inheriting from the node above anything that does not need to be changed.

Similarly, because a company is a company in the system, full supplier organizational structures can also be modelled according to their company structure and modelled down to the individual (factory) location. This is particularly important since a diversity initiative may be global but improvement efforts might be restricted to one factory producing one particularly unique component for one product line.

Then, the organization can configure, for that company:

- Account Plans

- for each supplier, the company can define the strategic objectives, guiding principles, and target behaviours; these can be defined from scratch or added from a common library

- Data Imports

- to define regular / repeating file-based imports

- Initiatives & Opportunities

- the overarching initiatives and/or opportunities being sought, the plans and project stages, questionnaires, suppliers, etc.; the form builder is section based, supports all standard HTML objects, and all of the (numeric) data collected can be subjected to metrics and rules (to map to binary/integer) which can be defined on multiple choices

- Performance

- allows a user to define the performance metrics / KPIs, organized into categories, that are to be tracked, define what levels they are tracked at / rolled up to, and even customize the metric calculation in individual nodes

- Permissions

- define the user permissions (by role)

- Projects

- centralizes the organizational projects

- Relationships

- define the supplier relationships by mapping the supplier to the specific nodes in the organizational structure where the relationship exists as well as the segment (division/category) they are servicing

- Reports

- define and customize the reports

- Statuses

- define the project states for initiatives and opportunities, rejections, suppliers, etc. as needed to match the organizational process; can start with defaults

- Surveys

- encapsulates all of the surveys that can be reused across initiatives and opportunities

- Tags

- custom tags for tagging initiatives, opportunities, suppliers, etc. for quick search & filter

- User Management

- define the organizational users

- Value Trackers

- defines, and centralizes, the metrics that will be used in the innovations, opportunities, and performance tracking

In summary, the administration is very powerful … in fact, it’s one of the few solutions where the organizational structure for all companies (buying and supplying organizations) is extensively customizable, where initiatives can be tailored to the subset of relevant relationships and locations, where the inheritance for an initiative can be customized, and where you fully customize and localize all supplier interactions to just the organizations and teams that you need.

This is the first aspect of Vizibl that truly makes it stand out. The degree of customization of initiatives only to the relationships of relevance, teams of relevance, with metrics of relevance is far beyond what most of the traditional “Relationship” solutions actually offer.

The second aspect of Vizibl that makes it stand out is the new program layer they’ve built to support the creation of programs that tie together all of the relevant SXM capabilities needed to completely manage an organizational initiative across the supply base. In many platforms, the organization needs to manage the surveys, performance metrics, reports, projects, collaborations separately across the different modules of the platform that were built up over time.

The third aspect of Vizibl that makes it stand out is the new Decarbonation-as-a-Service offering built on this program layer that integrates all of the platform capabilities to track carbon down to scope 3 across the supply chain, provide insight into best practices and learnings to reduce emissions, allow for the creation of projects and initiatives to tackle the opportunities, track improvement over time, and essentially turn measurement into action into improvement. Carbon calculators are a dime-a-dozen from everyone and their dog, and can be built in 15 minutes in any good modern (spend) analytics platform, but few platforms do real monitoring, few platforms allow for the creation of supplier development projects, and fewer still provide real insight into what can be done to get results.

In other words, if you really care about the “R” in Supplier Relationship Management, and truly want to manage that relationship for true supplier development and improvement, you should definitely make sure Vizibl is on your short-list.